working principles of hydraulic pump

What is the basic working principle of hydraulic system?

The basic principle behind any hydraulic system is very simple – pressure applied anywhere to a body of fluid causes a force to be transmitted equally in all directions, with the force acting at right angles to any surface in contact with the fluid. This is known as Pascal’s Law.

What is the basic working principle of automotive lift hydraulic pump?

The basic working principle of an automotive lift hydraulic pump involves using an electric motor to drive a hydraulic pump. This pump pressurizes hydraulic fluid, which is then directed through hydraulic lines to the lift cylinders. The pressurized fluid enters the cylinders, pushing pistons upwards to raise the lift arms and the vehicle. Lowering the vehicle is achieved by releasing the pressure on the hydraulic fluid, allowing gravity or a controlled release to lower the lift arms and vehicle safely. Valves within the system regulate the flow of hydraulic fluid, ensuring precise control over the lifting and lowering process.

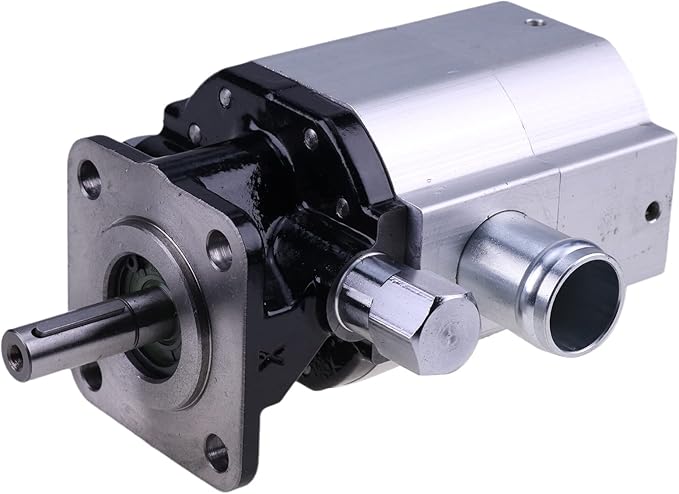

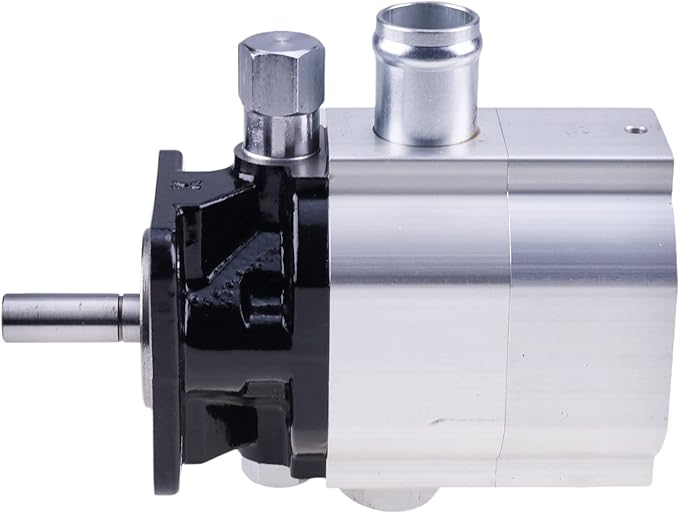

What is the basic working principle of bale bed hydraulic pump?

The basic working principle of a bale bed hydraulic pump involves using a power take-off (PTO) from the vehicle’s engine or a separate hydraulic power unit (HPU). This power source drives a hydraulic pump, which pressurizes hydraulic fluid. The pressurized fluid is then directed through hydraulic lines to hydraulic cylinders located on the bale bed.

When the hydraulic fluid enters the cylinders, it pushes pistons or rams outward, extending the bed and lifting the load, such as bales of hay or other materials. Reversing the flow of hydraulic fluid allows the bed to retract and lower the load. Valves and control mechanisms regulate the flow and pressure of the hydraulic fluid, ensuring smooth operation and precise control of the bale bed’s movements. This hydraulic system provides efficient and powerful lifting capabilities for agricultural and industrial applications.